RENHOTEC GROUP, Chinese RJ45 connector manufacturer for more than 12 years with ISO certified. We have rich experience in OEM and could provide suitable project plan with competitive price for customer. Now ,Let’s us introduce some knowledge of the RJ45 connectors.

RJ45 is a kind of information socket(communication terminal)connector in the wiring system, which is consists of a plug(connector, crystal head) and a socket(module).The plug has 8positions and 8 contacts. RJ is an abbreviation for Registered Jack, meaning "registered socket".In the FCC (United States Federal Communications Commission Standards and Regulations), RJ is the interface of the public telecommunication network,and the RJ45 of the computer network is the common name of the standard 8-bit modular interface.

RJ45 connector has 8 pins, which means an RJ45 cable contains 8 separate wires.You can see the eight different color wires, If you look closely at the end of an Ethernet cable. Four of them are striped, and the other four are solid colors . Usually, for the RJ series products, we can see xPyC, so what is it? Here below you can get the meanings:

P = Positions C = Contacts

x = number of available Positions for Contacts which is the physical SIZE of the connector.

y = number of Contacts installed in the above size and the number of conductors in the cable.

For example:

1.6P6C is a 6 Position with 6 Contacts and wires. This also goes by the name RJ11

2..8P8C is a 8 Position with 8 Contacts and wires. This also goes by the name RJ45.

Category

The RJ series are basically named on the FCC standards and regulations. The numbers following the RJ represent the number of wires. Normally ,the RJ series have these kinds of types:

RJ11, RJ14, RJ25 telephone line interface (respectively for a pair, two pairs, three pairs),RJ45 Ethernet interface (network interface).

More classification as below:

1.Gender: Female/Male

2.Orientation: Vertical/Straight/180 degree/Side entry Right Angle/90 degree/45 Degree

3.Terminal Type:Through-hole(DIP)/SMT Type

4.Port:Single Port/Muti-port:for example:1×1,1×2,1×4,1x6,1x8/2×1,2×2,2×3,2×6

5.Function:Shielded/Unshielded, and the shield has full metal shielded and half-cover shielded,which is with shrapnel or not.

6.With/without leds

7.With transformer/Magnetic or without

Wiring

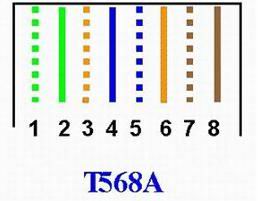

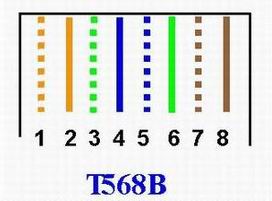

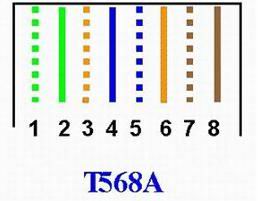

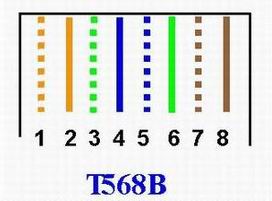

RJ45 can be wired the cables in two different ways. One is named T-568A ,and the other is T-568B. The T-568B wiring scheme is the most common, but many devices support the T-568A wiring scheme as well. Some networking applications need a crossover Ethernet cable, which has a T-568A connector on the one end and on the other for a T-568B connector. This kind of cable is regular used for direct computer-to-computer connections when there is no router, hub, or switch available.

These 2 wiring standards are listed below:

| T-568A

1. White/Green (Receive +)

2. Green (Receive -)

3. White/Orange (Transmit +)

4. Blue

5. White/Blue

6. Orange (Transmit -)

7. White/Brown

8. Brown |

T-568B

1. White/Orange (Transmit +)

2. Orange (Transmit -)

3. White/Green (Receive +)

4. Blue

5. White/Blue

6. Green (Receive -)

7. White/Brown

8. Brown |

Application

RJ series connectors are widely used in civil, industrial, medical, communications and other fields.In the Civilian areas, such as: telephone, network adapter, PC Notebook,Router/Switch, Wireless Router,Hubs, printers, security cameras, game consoles and other devices.

Article Source: http://www.renhotecpc.com/knowledge/the-rj45-connectors-product-knowledge-introduction/

Scan or click the QR code to chat online via WeChat

Scan or click the QR code to chat online via WeChat